Though the term clamshell may apply to a number of devices that consist of two hinged parts and open and close in a fashion similar to the two shells of a clam, it is most commonly applied to the plastic packaging of this design. Read More…

Valk’s policy is “to meet or exceed our customer’s requirements, working together as a team with honesty and integrity.” Valk’s success is due to their long standing focus on quality & customer service.

Since 1960, Profile Plastics Inc. has been at the forefront of thermoforming technology. Utilizing the latest software and technology, our expert staff of engineers can design custom vacuum, pressure, and twin-sheet thermoformed solutions. Over the last 60 years, we have developed a process that allows us to deliver consistent, high volume, and precise products with superior quality. Our high...

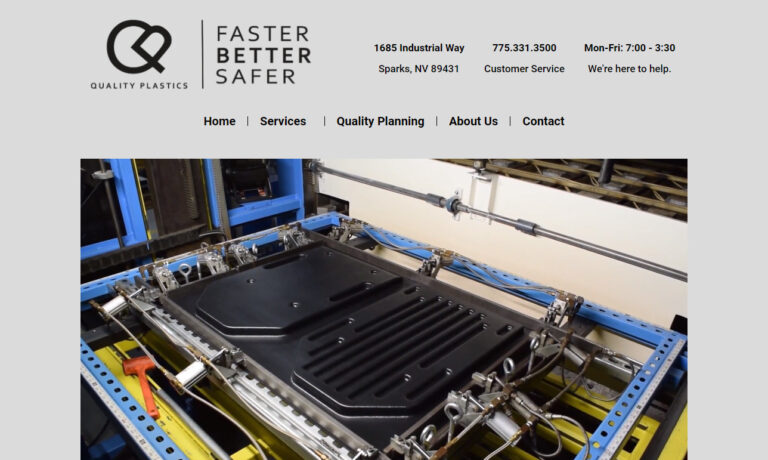

Quality Plastics has been a leading manufacturer of vacuum forming since 1976. Whether you need a small batch of custom vacuum-formed parts or a large-scale production run, we have the capabilities and expertise to deliver. We are committed to providing our customers with exceptional vacuum-formed products and services that meet their needs and exceed their expectations. Contact us today to learn ...

Engineered Plastic Products custom forms & fabricates sheet thermoplastic materials, standard & specialized, for any number of industrial & commercial requirements. EPP has been widely recognized for outstanding manufacturing & service since 1958 for companies such as GE, NASA & AT&T. Custom fabricated parts can be as large as 72"x108" down to 2"x2" in any thickness up to 1 1/2". Post-forming...

At Lerner Molded Plastics, we specialize in crafting high-quality vacuum-formed products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.

RapidMade is a leader in thermoforming and vacuum forming solutions, offering unmatched customer experience, quality, and speed. We cater to diverse needs with a broad material and equipment portfolio, ensuring cost-effective, engineered parts. Trust us for reliable, timely delivery of your small to medium batch plastic projects, meeting the highest industry standards. Choose RapidMade for...

At Duo Form, we are pioneers in the realm of vacuum-formed plastic products. With a collective passion for precision engineering and creative problem-solving, we've established ourselves as leaders in delivering high-quality solutions to a wide range of industries.

Robinson Industries offers thermoformed and injection molded reusable, heavy duty plastic pallets, packaging and more. We are one of the largest suppliers of reusable pallets to many industries.

More Clamshell Companies

Most commonly made of clear polyvinyl chloride or PVC, durable clamshell containers are preferred by retailers as they provide increased product visibility from several different angles. Clamshells also protect products from environmental factors while deterring theft and tampering as they are difficult to open, often requiring the use of a knife or scissors. Despite there rugged construction, clamshells are lightweight with a high strength to weight ration that makes them suitable and inexpensive for product display, packaging and shipment.

Such versatility makes clamshells among the most popular plastic packaging forms available and they are commonly employed in such varied industries as food, cosmetic, medical, entertainment, household appliances, office supply, packaging, clothing, retail and electronics. Custom and stock forms are widely available in a number of different shapes and sizes. Molds are often based off of a specific product to ensure the best fit and visibility.

A number of plastic forming processes can be implemented in the production of clamshell containers. Thermoforming and vacuum forming processes begin with sheets of PVC that are fed into electric, natural gas or infrared heaters. Materials are warmed until they become pliable and soft, at which point they are guided into a forming station. A mating mold and pressure box enclose the sheet before a vacuum is used to remove all excess air, pulling the plastic into the mold.

Pressure forming is used when precision molding is desired or required as high air pressure causes greater adherence to the mold allowing for the production of finer detail in the finished clamshell than thermoforming alone. In either case, the PVC is cold while still on the mold. Once rigid reverse air flow ejects the clamshell which may be two separate components or on a single sheet that is folded to create a hinge.

Once the product is placed within the shell, the edges are fused through heat treatments, welding or stamping to create an airtight case. The most common types of clamshells include tri-fold clamshells which have a flat bottom for standing on display, clamshell trays which combine packaging with product display and egg crate clamshells which hold and divide several like products such as golf balls.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services