Plastic packaging is a type of packaging manufactured from plastic. Food packaging, beverage packaging, and medical packaging are just a few examples of products that use plastic packaging. Plastic packaging is frequently used because it is strong, portable, and simple to form into many shapes. In addition, it is portable because of its light weight. Read More…

Valk’s policy is “to meet or exceed our customer’s requirements, working together as a team with honesty and integrity.” Valk’s success is due to their long standing focus on quality & customer service.

Since 1960, Profile Plastics Inc. has been at the forefront of thermoforming technology. Utilizing the latest software and technology, our expert staff of engineers can design custom vacuum, pressure, and twin-sheet thermoformed solutions. Over the last 60 years, we have developed a process that allows us to deliver consistent, high volume, and precise products with superior quality. Our high...

Quality Plastics has been a leading manufacturer of vacuum forming since 1976. Whether you need a small batch of custom vacuum-formed parts or a large-scale production run, we have the capabilities and expertise to deliver. We are committed to providing our customers with exceptional vacuum-formed products and services that meet their needs and exceed their expectations. Contact us today to learn ...

Engineered Plastic Products custom forms & fabricates sheet thermoplastic materials, standard & specialized, for any number of industrial & commercial requirements. EPP has been widely recognized for outstanding manufacturing & service since 1958 for companies such as GE, NASA & AT&T. Custom fabricated parts can be as large as 72"x108" down to 2"x2" in any thickness up to 1 1/2". Post-forming...

At Lerner Molded Plastics, we specialize in crafting high-quality vacuum-formed products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.

RapidMade is a leader in thermoforming and vacuum forming solutions, offering unmatched customer experience, quality, and speed. We cater to diverse needs with a broad material and equipment portfolio, ensuring cost-effective, engineered parts. Trust us for reliable, timely delivery of your small to medium batch plastic projects, meeting the highest industry standards. Choose RapidMade for...

At Reliable Formed Plastics, we provide vacuum forming for the food and beverage, retail, aerospace, and OEM industries. Most thermoplastic sheet materials including ABS, acrylic, polycarbonate, and polypropylene can be used to create custom displays, enclosures, and consumer goods.

Robinson Industries offers thermoformed and injection molded reusable, heavy duty plastic pallets, packaging and more. We are one of the largest suppliers of reusable pallets to many industries.

More Plastic Packaging Companies

Types of Plastic Packaging

Certain types of packaging calls for certain plastics. The most popular plastic varieties, their characteristics, and their everyday uses will be covered in this guide on plastic packaging.

Polyethylene Low Density (LDPE)

This plastic, one of the most widely made ones, is resistant to bases, acids, and oils. It is straightforward to make, flexible, transparent, and hard. Packaging for food and drinks can be made safely using LDPE.

Typical uses comprise:

- Heat-sealing required packaging

- Trash bags

- Plastic bags

- Coatings on cartons and mugs for beverages

- Shrink wrap and stretch film

- Condiment squeeze bottles

- Bags of frozen and fresh produce

- Movable lids

- Cables and wires

This plastic may be recycled and is often used to create new plastic bags, floor tiles, and shipping envelopes.

Polyethylene High Density (HDPE)

The most popular plastic for packaging is HDPE. It is resilient, robust, and resistant to solvents and chemicals. In addition, since HDPE has a greater tensile strength than other plastics, it is more resilient and able to resist higher temperatures.

Typical uses comprise:

- Bottles for drinks and beverages

- Shampoo and conditioner bottles

- Household cleaning supplies

- Shopping bags

- Box liners for cereal

Both varieties of polyethylene have the drawback of requiring a lot of energy to create. HDPE can be recycled, though it can be a difficult process. It frequently ends up being repurposed into brand-new pots and containers.

Polypropylene (PP)

The plastic PP has a high melting point, is chemically resistant, and transmits moisture slowly. Due to this, it works perfectly to hold hot liquids.

Among the frequent uses are:

- Pharmacy bottles

- Syrup containers

- Yogurt bottles

- Containers for deli and takeout meals

- Bottle tops and closures

UV radiation breaks down polypropylene, making it unsuitable for use in environments with strong UV ray exposure. It is also difficult to paint on due to its surface, making printing difficult. When recycled, it is frequently used to create items for vehicles, tools, and containers.

Polyethylene terephthalate (PET)

Polyethylene terephthalate (PET) is a plastic with good moisture and gas barrier qualities, making it ideal for food containers. It effectively prevents oxygen from destroying the object. In addition, it contains the carbon dioxide in fizzy drinks and protects them. Additionally, PET is smooth, transparent, and shatterproof.

Typical applications include:

- Soft drink bottles

- Bottles of juice, beer, and other drinks

- Packaging for mouthwash

- Jars for jelly and condiments in food

- Meals in a microwave

This form of plastic is inappropriate for some liquid containers because of its poor heat resistance. In addition, the recycled plastic flakes used to make these carpets and other fabrics are in high demand.

Vinyl Chloride Polymer (PVC, Vinyl)

PVC is the third most produced plastic in the world. As a result of its resistance to chemicals and oil, it is widely used. In addition, it is powerful and incredibly clear, thanks to its stable physical characteristics.

Typical uses comprise:

- Clamshells

- Biffer packets

- Shrink wrap for use in medicine

- Packaging for meat and deli

- Heavy-duty bags for packaging

There are worries that the PVC production process leaves harmful material behind. It is also the plastic type that is least friendly to the environment. To compensate, PVC is recyclable and frequently used to make building materials.

Polystyrene

It has a high melting point and can be stiff or foamed. It acts as a moisture barrier and is rigid with insulating qualities.

Typical uses comprise:

- Single-use plates, glasses, and cutlery

- Trays for meat and poultry

- Yogurt bottles

- Egg crates

- Clamshell-shaped takeout ware

- packing that is protective for electrical and fragile items

UV light deteriorates this kind of brittle plastic, making it less durable. It is also quite explosive, making it dangerous for several industries. One plastic with a very low rate of recycling is polystyrene. However, recycled polystyrene can create moldings for construction projects, electrical outlet casings, and camera casings.

Polyethylene Terephthalate Glycol (PETG)

PETG, a copolymer, is a durable, clear, glossy, and cost-effective plastic with high chemical resistance. Additionally, it is completely recyclable and free of BPA. Due to its low forming temperatures, it may be cleaned with ease. PETG is also used in 3D printing, despite not primarily used for packaging.

Typical uses comprise:

- Medical and pharmaceutical tubes

- Cosmetic packaging

- Blister packs for equipment and office supplies

- Packaging for electronics and food

This kind of plastic has the fewest drawbacks. The material's potential for heat degradation should be the key concern.

CAB (Cellulose Acetate Butyrate)

CAB, which contains up to 55% butyryl, is an essential plastic for usage in industries. CAB has a high-gloss surface and is robust, sturdy, and resistant to heat.

Typical uses comprise:

- Candy, toys, cosmetics, and craft supply tubes

- Clear postal tubes

- Equipment packaging

- Printed-out inks

- Topcoats for nail polish

Additionally, CAB can enhance the hardness and glossiness of coatings.

CAP (Cellulose Acetate Propionate)

CAP is tough, rigid, and robust. It has a high-gloss surface and is heat-resistant. It can be clear, translucent, or colored.

Typical uses comprise:

- Candy, toys, cosmetics, and craft supply tubes

- Items for POP (point-of-purchase) displays

- Other tube-shaped containers

The weak solvent and alkaline resistance of both cellulose-based plastic types render them unsuitable for use with specific liquids. They can catch fire as well.

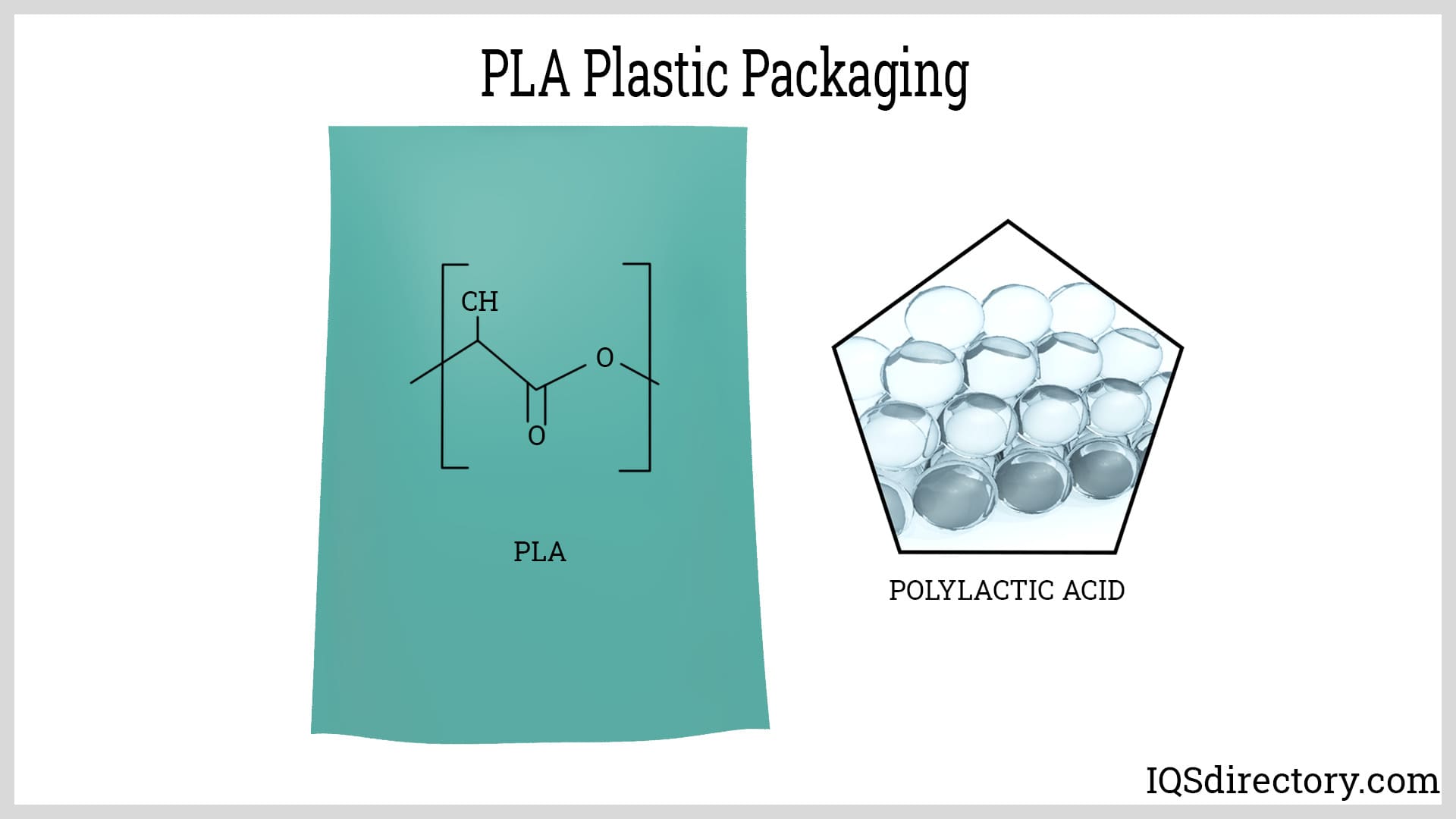

PLA (Polylactic Acid) (Polylactic Acid)

PLA is biodegradable and produced from basic renewable materials. PLA is a material that has been hailed as a solution to non-recyclable plastics since it is suitable for use in food and drink containers.

Typical applications for PLA include:

- Remove the cups

- Remove boxes

- Fruit and vegetable containers

- Plastic sheets

- Plastic containers

Natural PLA is manufactured from sugar cane or corn starch and is intended to biodegrade. Therefore, it may be produced without using crude oil, unlike many other polymers. The drawback of being biodegradable is that it can not simply be dumped in a compost pile and expected to break down. For PLA to degrade correctly, the required conditions must be offered.

What Plastic Packaging Means

In this modern life, plastic packaging provides several essential purposes, which are the main reasons we depend on it:

Protection: Plastic packaging guards against harm to delicate items during transport and contamination from moisture, humidity, gasses, bacteria, insects, and light.

Preservation: By preserving goods for a longer period, individuals have more opportunities to utilize or consume them before they are no longer suitable, decreasing waste. Waste is also avoided by keeping products together and avoiding spills.

Transport: Enables the movement of goods across long distances, giving us access to a wide range of non-local produce that, in turn, promotes trade. Additionally, stacking items increases the effectiveness of transportation while saving space.

Information: Information on the packaging includes details about the product's nutritional value and allergy warnings.

Selecting the Correct Plastic Packaging Company

To ensure you have the most productive outcome when selecting a plastic packaging company, it is important to compare several companies using our directory of plastic packaging businesses. Each plastic packaging company has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each plastic packaging company using our patented website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple plastic packaging companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services