Plastic forming is a method of designing, manufacturing, and assembling a product that is made from plastic. Plastic material is used in various ways in our daily life, and the plastic industry is growing daily. According to experts, plastic production may continue to grow and reach 540 million metric tons by 2040. Read More…

Valk’s policy is “to meet or exceed our customer’s requirements, working together as a team with honesty and integrity.” Valk’s success is due to their long standing focus on quality & customer service.

Since 1960, Profile Plastics Inc. has been at the forefront of thermoforming technology. Utilizing the latest software and technology, our expert staff of engineers can design custom vacuum, pressure, and twin-sheet thermoformed solutions. Over the last 60 years, we have developed a process that allows us to deliver consistent, high volume, and precise products with superior quality. Our high...

Quality Plastics has been a leading manufacturer of vacuum forming since 1976. Whether you need a small batch of custom vacuum-formed parts or a large-scale production run, we have the capabilities and expertise to deliver. We are committed to providing our customers with exceptional vacuum-formed products and services that meet their needs and exceed their expectations. Contact us today to learn ...

Engineered Plastic Products custom forms & fabricates sheet thermoplastic materials, standard & specialized, for any number of industrial & commercial requirements. EPP has been widely recognized for outstanding manufacturing & service since 1958 for companies such as GE, NASA & AT&T. Custom fabricated parts can be as large as 72"x108" down to 2"x2" in any thickness up to 1 1/2". Post-forming...

At Lerner Molded Plastics, we specialize in crafting high-quality vacuum-formed products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.

RapidMade is a leader in thermoforming and vacuum forming solutions, offering unmatched customer experience, quality, and speed. We cater to diverse needs with a broad material and equipment portfolio, ensuring cost-effective, engineered parts. Trust us for reliable, timely delivery of your small to medium batch plastic projects, meeting the highest industry standards. Choose RapidMade for...

At Designcraft, we pride ourselves on being pioneers in the field of innovative design and manufacturing solutions. We specialize in vacuum forming, a versatile and cost-effective method for creating high-quality plastic components. Our team of skilled engineers and designers work tirelessly to ensure every product we produce meets the highest standards of precision and durability.

Robinson Industries offers thermoformed and injection molded reusable, heavy duty plastic pallets, packaging and more. We are one of the largest suppliers of reusable pallets to many industries.

More Plastic Forming Companies

Plastic forming is a method of designing, manufacturing, and assembling a product that is made from plastic. Plastic material is used in various ways in our daily life, and the plastic industry is growing daily. According to experts, plastic production may continue to grow and reach 540 million metric tons by 2040. The plastic industry has taken over our kitchens, wardrobes, electronics, and more. Plastic is used in consumer goods, electronics, toys, kitchen appliances, and electrical and industrial machinery.

Properties of Plastic

- Plastics are lightweight and can be molded easily into any shape and size.

- They are chemically stable, with good rust resistance.

- Plastic has good insulation and low thermal conductivity.

- Plastic is transparent and has poor dimensional stability.

- Plastic material is low–cost and easy to process.

Types of Plastic

There are two types of plastic. These are:

Thermosetting Plastic

Thermosetting plastic, also called thermosets, is plastic that does not undergo any changes in shape once heated and molded. These plastics degrade, deter, and are destroyed on reheating. Common examples are epoxy resin, rubber, polyurethane, etc.

Thermoplastic

Thermoplastic does not change its chemical composition and can be remolded multiple times. Common examples are polystyrene, Teflon, acrylic, and nylon.

Manufacturing Process of Plastic

Plastic forming involves many different processes, and each depends on the type of product and the plastic used. The manufacturing process consists of the following steps:

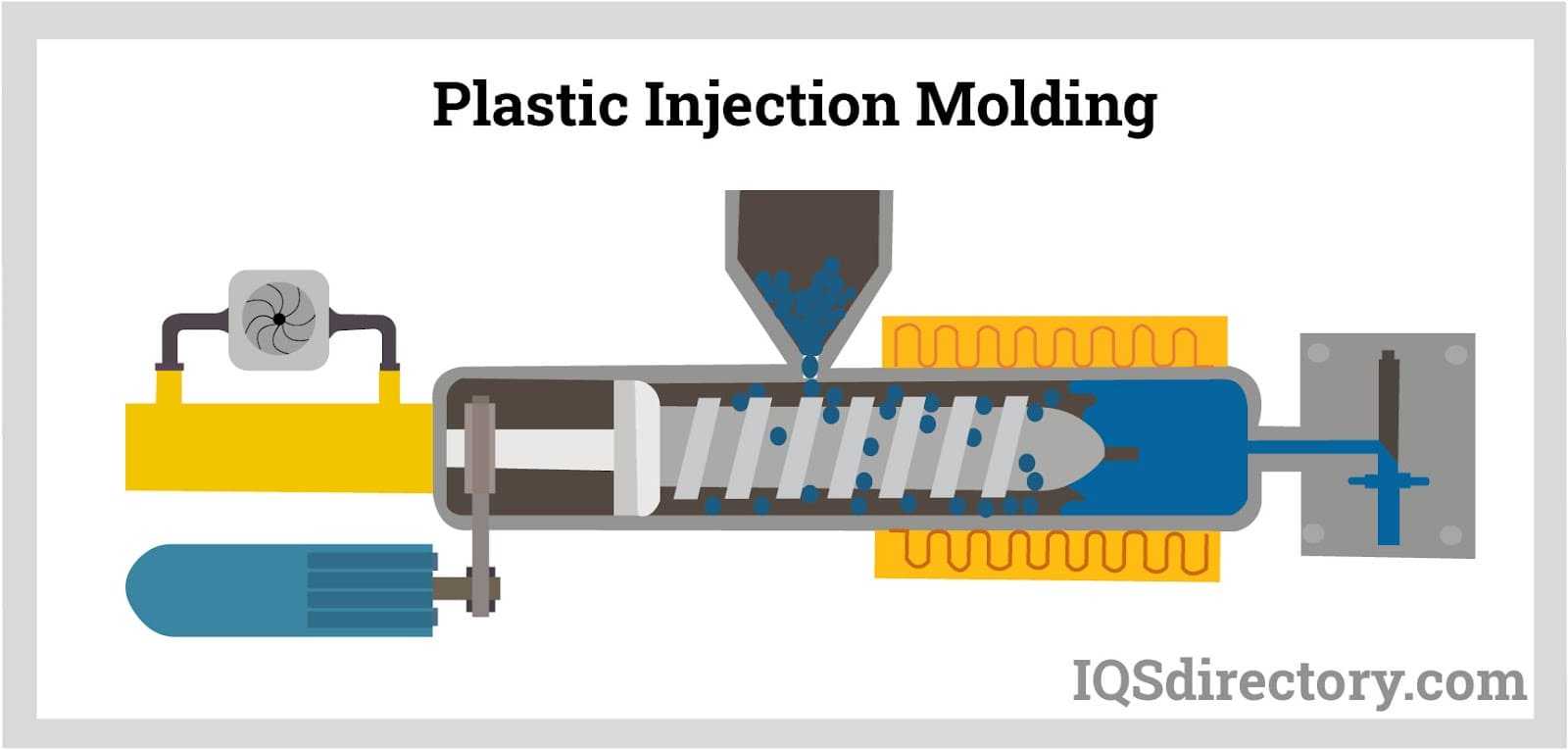

Plastic Injection Molding

- This method uses a mold made of aluminum or steel.

- The mold, consisting of a core and an inner cavity, is placed in the machine.

- The heated plastic pallets are injected into the molds and then cooled.

- About 80% of plastic items that we use in our daily life are made by this process.

- It is a low-cost process that gives an excellent finish, and millions of the same products can be made rapidly.

- Molds can be expensive, so proper engineering and cleaning are required to prevent mold defects.

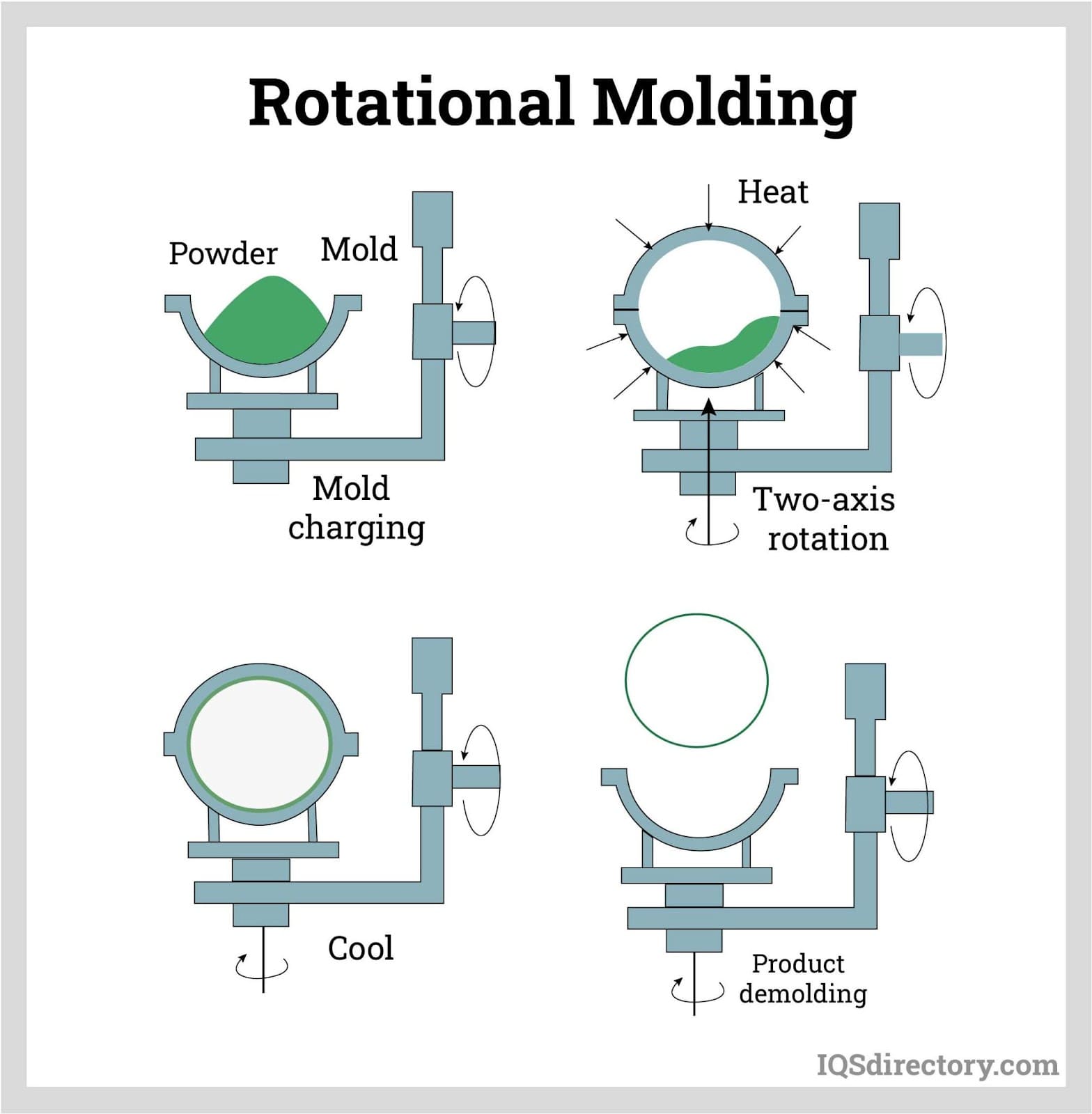

Rotational Molding

- In this process, plastic powder is poured into molds and then placed in the ovens.

- While heating, the mold is rotated slowly on two axes, and gravity is used to stick the powder to the mold walls.

- The heated plastic is then cooled down slowly to prevent disfiguration.

- This molding is best for making concave or hollow shapes and large products such as tubs.

- It is an inexpensive process; the product formed is strong and fault-free.

- The tools are to be changed after a few thousand cycles, and the method is not best for precision forming.

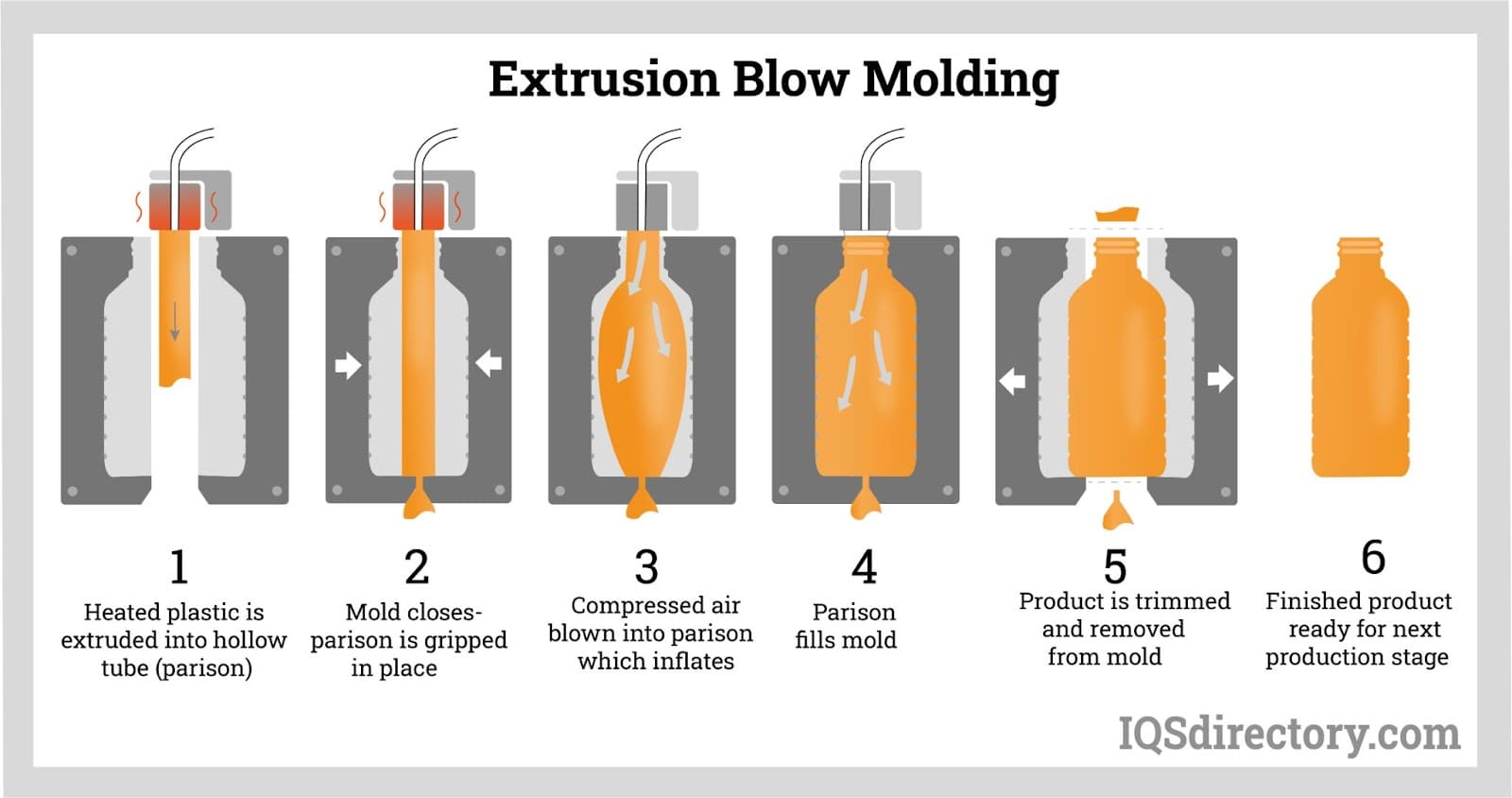

Extrusion Blow Molding

- This molding is done to make inexpensive products such as disposable cups and bottles.

- It is a fast process, and the tools are easy to make.

- Molten plastic takes the form of a large droplet, called a parison, and is placed in a two-piece clamshell mold.

Injection Blow Molding

- In injection molding, pressure is used to place the molten plastic in the molds.

- It is used to make transparent plastic bottles and is easily controlled and a repeatable process.

- These are not ideal for thin walls. However, these are durable and safe to consume.

Reaction Injection Molding

- RIM is used in the automotive industry as it makes light-weighted parts with rigid skin.

- Thermosetting plastic expands like foam on heating and fills the mold.

- Production tooling is expensive for RIM.

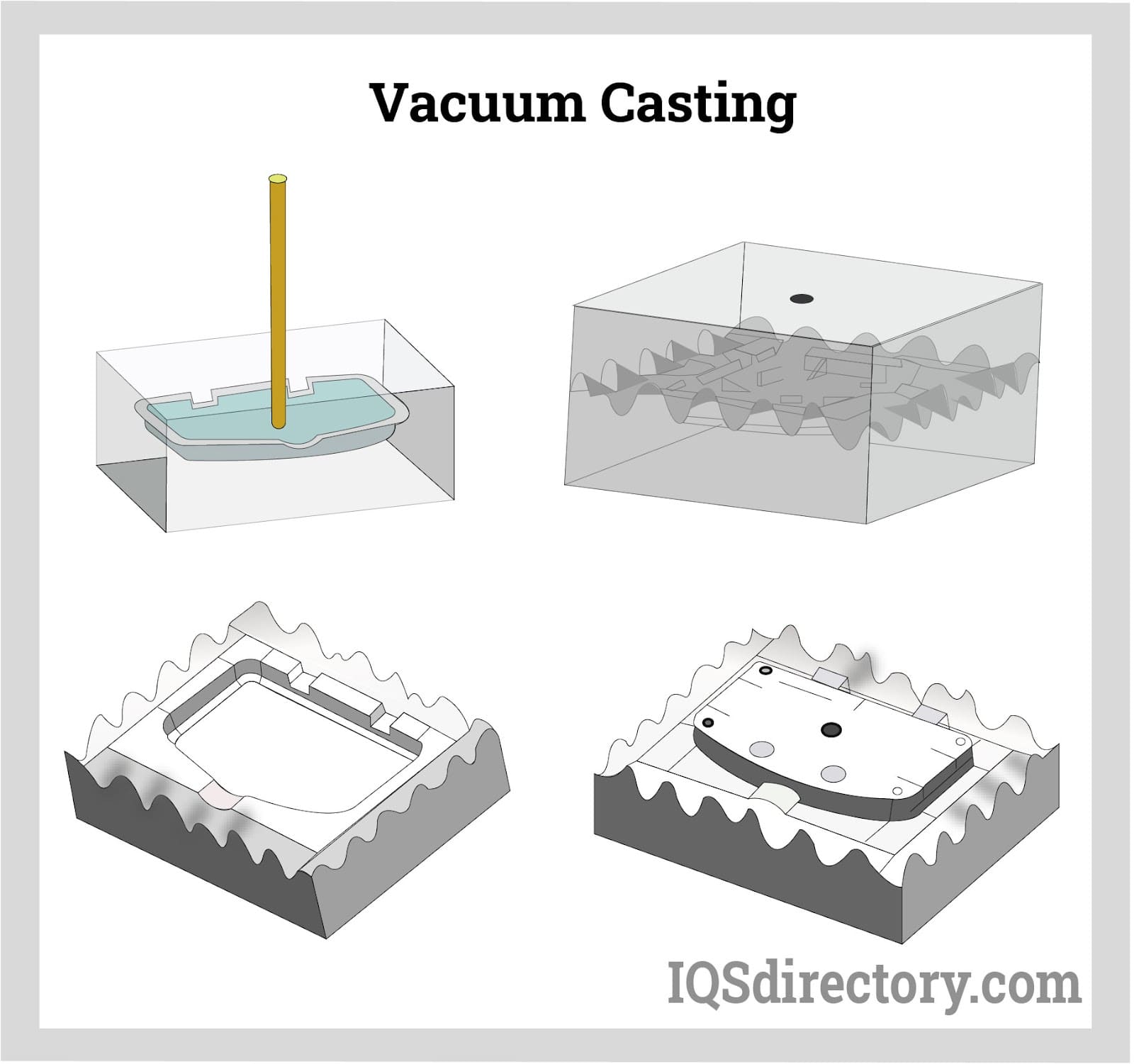

Vacuum Casting

- A master model is placed in a sealed box filled with flexible urethane or silicone.

- When removed, it forms a cavity in the mold, which is then filled with resin.

- The air bubbles are removed by using vacuum pressure.

- These molds are not durable and will degrade after 20 or more copies.

Thermoforming

- A thin or thick plastic sheet is placed on the die, and the rising temperature makes the material pliable.

- It is used for prototypes of thin-walled and hollow-bodied parts.

- It is used to make plastic cups, lids, boxes, and plastic packaging.

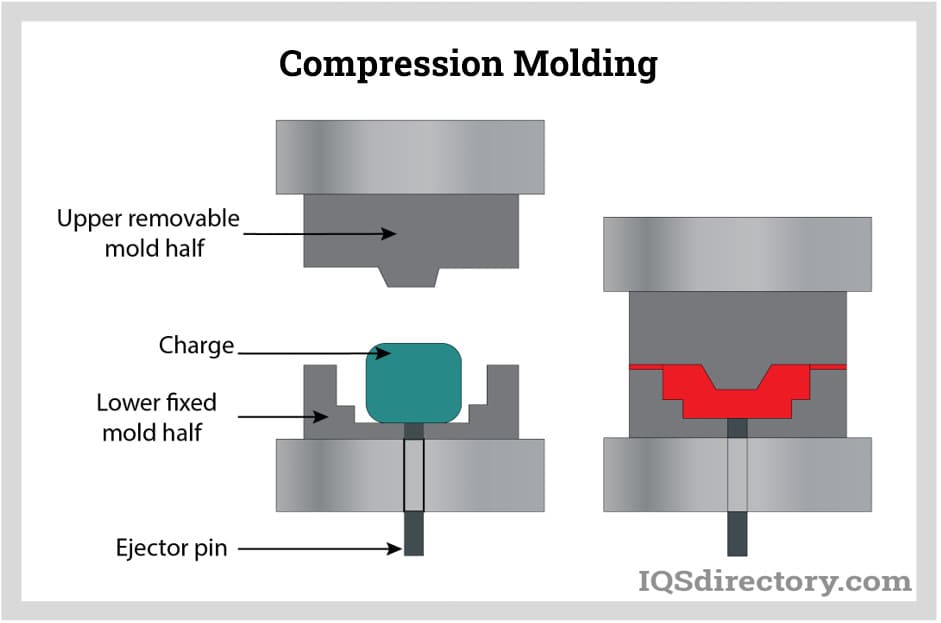

Compression Molding

- The raw material used in this process is pre-heated and placed in the cavity.

- A cap or a plug is used to cover the die, and heat and pressure are applied.

- It is used to make rubber keypad switches, gaskets, and o-rings.

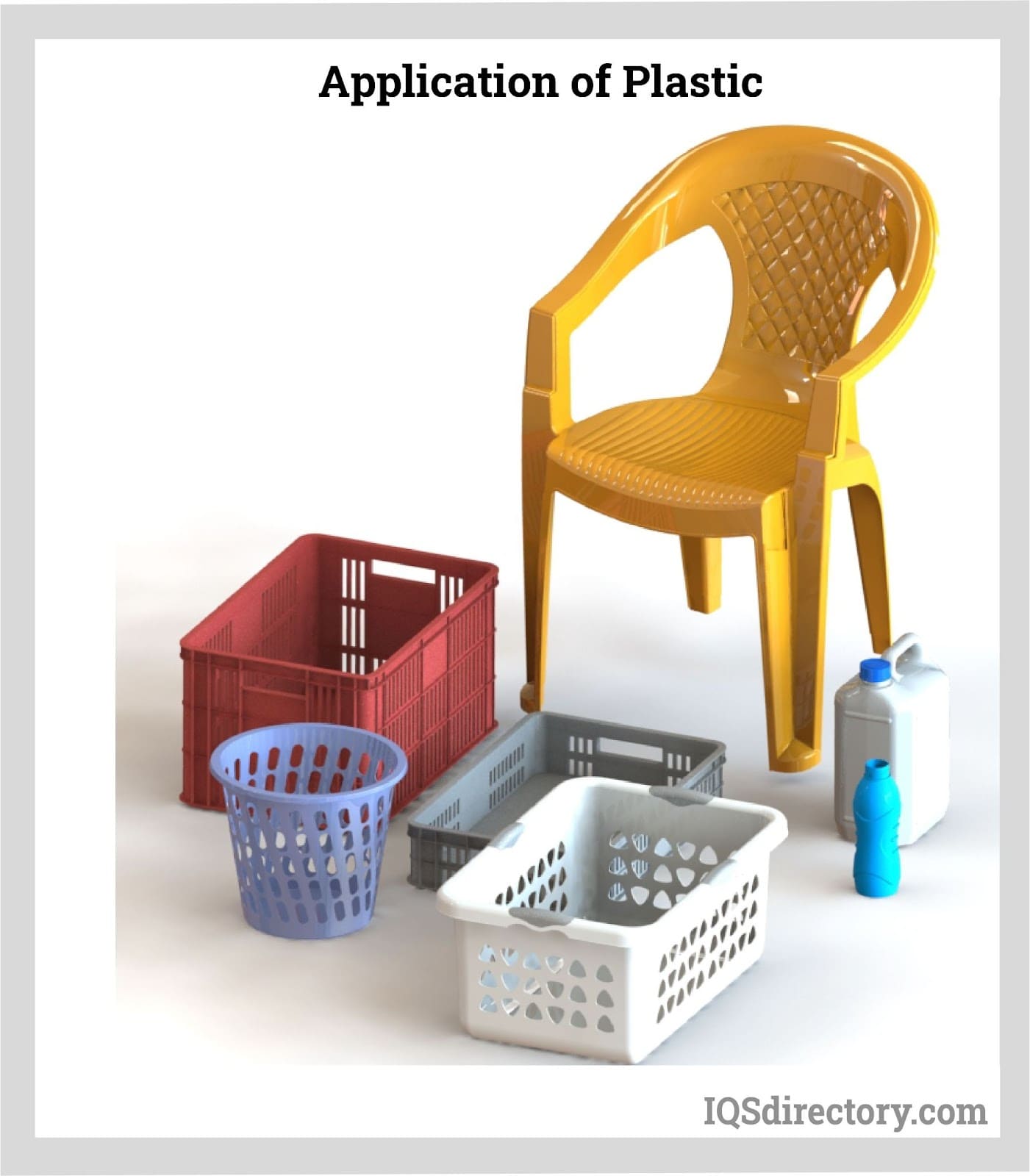

Application of Plastic

Plastic material is used in home items such as vacuum cleaners, television, sound systems, chairs, tables, appliances, electronics, utensils, automobiles, space stations, pipes, gaskets, cladding, food packaging, food containers, medical equipment, children safety gears, and many more.

Choosing the Proper Plastic Forming Company

For the most positive outcome when choosing a plastic forming company, it is important to compare several plastic forming businesses using our directory of plastic forming companies. Each plastic forming company has a business profile page that highlights their areas of experience and capabilities, as well as a contact form to directly communicate with the business for more information or request a quote. Review each plastic forming business using our proprietary website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple plastic forming businesses with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services