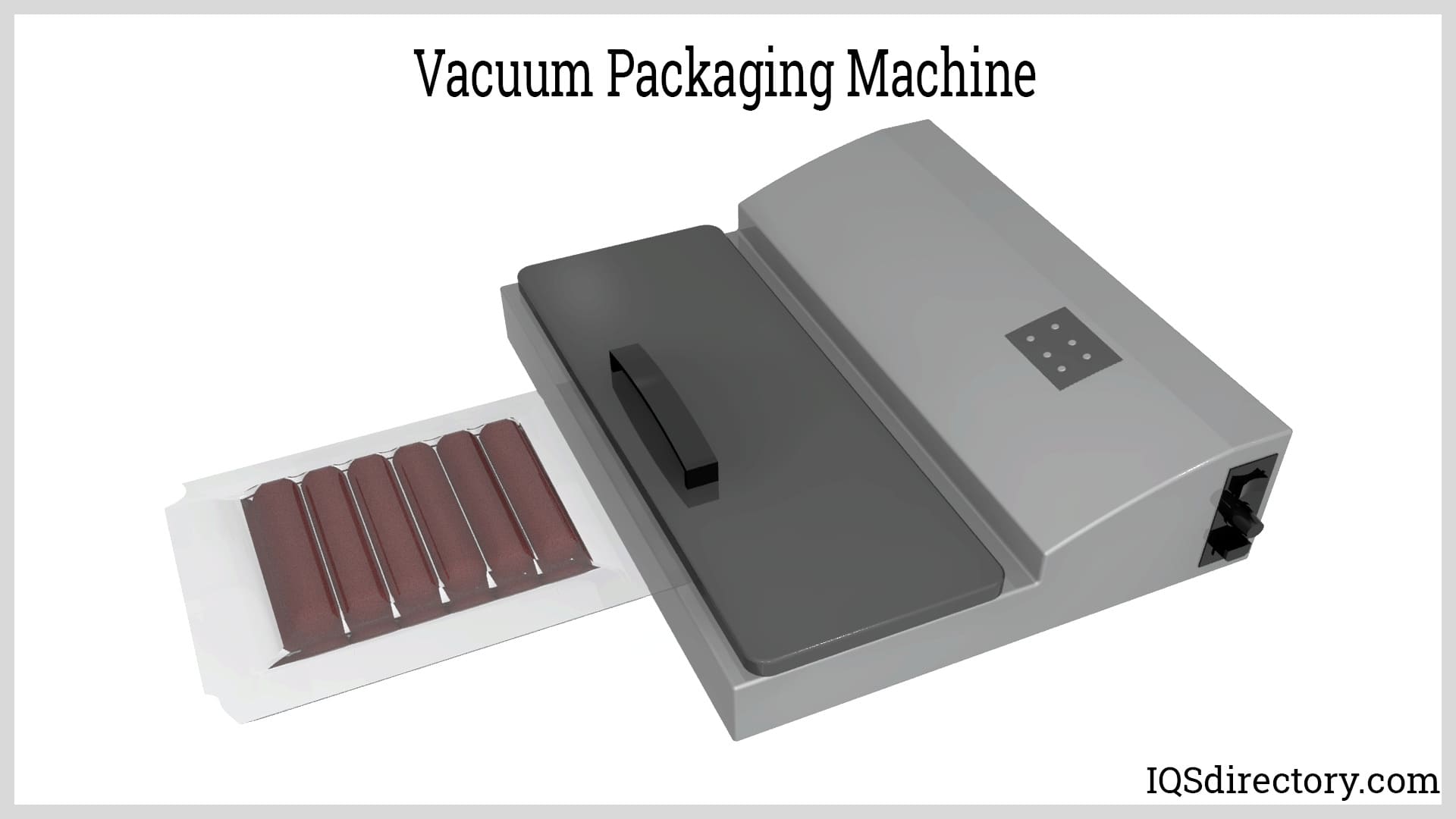

Vacuum packaging is a type of modified atmosphere packaging. Vacuum packaging’s main objective is to completely or partially eliminate oxygen, which frequently causes degradation. A combination of oxygen and nitrogen may be included inside the vacuum packaging to increase shelf life, depending on the type of products being wrapped. Read More…

Valk’s policy is “to meet or exceed our customer’s requirements, working together as a team with honesty and integrity.” Valk’s success is due to their long standing focus on quality & customer service.

Since 1960, Profile Plastics Inc. has been at the forefront of thermoforming technology. Utilizing the latest software and technology, our expert staff of engineers can design custom vacuum, pressure, and twin-sheet thermoformed solutions. Over the last 60 years, we have developed a process that allows us to deliver consistent, high volume, and precise products with superior quality. Our high...

Quality Plastics has been a leading manufacturer of vacuum forming since 1976. Whether you need a small batch of custom vacuum-formed parts or a large-scale production run, we have the capabilities and expertise to deliver. We are committed to providing our customers with exceptional vacuum-formed products and services that meet their needs and exceed their expectations. Contact us today to learn ...

Engineered Plastic Products custom forms & fabricates sheet thermoplastic materials, standard & specialized, for any number of industrial & commercial requirements. EPP has been widely recognized for outstanding manufacturing & service since 1958 for companies such as GE, NASA & AT&T. Custom fabricated parts can be as large as 72"x108" down to 2"x2" in any thickness up to 1 1/2". Post-forming...

At Lerner Molded Plastics, we specialize in crafting high-quality vacuum-formed products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.

RapidMade is a leader in thermoforming and vacuum forming solutions, offering unmatched customer experience, quality, and speed. We cater to diverse needs with a broad material and equipment portfolio, ensuring cost-effective, engineered parts. Trust us for reliable, timely delivery of your small to medium batch plastic projects, meeting the highest industry standards. Choose RapidMade for...

At Designcraft, we pride ourselves on being pioneers in the field of innovative design and manufacturing solutions. We specialize in vacuum forming, a versatile and cost-effective method for creating high-quality plastic components. Our team of skilled engineers and designers work tirelessly to ensure every product we produce meets the highest standards of precision and durability.

Robinson Industries offers thermoformed and injection molded reusable, heavy duty plastic pallets, packaging and more. We are one of the largest suppliers of reusable pallets to many industries.

More Vacuum Packaging Companies

Consumable goods are not the only items that can be vacuum packaged. Other non-consumable goods come in a wide range and are frequently vacuum packaged. Vacuum packaging is a great choice for any products that are delicate to moisture, dust, or other environmental factors.

Shrink wrap packaging is an additional common alternative for products susceptible to environmental factors. However, there are several significant distinctions between shrink-wrap packaging and vacuum packaging, despite the common misconception that they are interchangeable.

Vacuum Packaging Process

In the vacuum packaging process, the air is first removed from the package using an extractor to draw it out. After that, the package is hermetically sealed to prevent air from entering. External suction machines or chamber machines can be used to extract air; the choice of machine is typically based on the type of food that will be packaged.

By removing the air, an unfavorable environment is created for aerobic microorganisms like bacteria and mold, which die in the lack of oxygen They cannot alter the color, texture, and aroma of food, nor do they affect the nutrients (proteins, vitamins, and carbohydrates). Additionally, drying occurs because of vacuum preservation because water under low pressure evaporates and is released outside. Dry conditions limit the growth of bacteria and mold.

Vacuum Packaging Benefits

Due to the longer shelf life of the food, decreased weight loss from controlling evaporation, protection from contamination, color preservation, and superior eating attributes due to the longer aging that is achievable in vacuum bags, vacuum packaging has certain unique advantages.

Saves Time

By packaging the quantity needed for each meal, one can save time. Food that has been vacuum-sealed is typically kept in the refrigerator and used one at a time. Therefore, it will save time later when it is utilized to keep different portions of material vacuum-sealed in separate bags.

Cost Effective

Using vacuum packaging, one can store food for a very long time, which might lead to cost-effective solutions. For example, when purchasing items like beef in bulk, money can be saved compared to purchasing it individually. Therefore, vacuum packaging reduces costs.

Preserves Food

One thing vacuum sealing can do is preserve products and their characteristics. There is no atmospheric influence in a vacuum, so there is very little danger of receiving spoiled produce.

Protection of Food

Products that are vacuum sealed are properly protected. They are not at risk of being burned or having any changes made to them by freezing. Additionally, a vacuum bag ensures that no water comes in contact with the food inside. It offers a comprehensive approach to food safety.

Extended Shelf Life

The food within has a considerably longer shelf life thanks to the vacuum. According to data, food appears to survive 3 to 5 times longer in a vacuum-sealed bag. Depending on where vacuum-sealed goods is stored, the amount may change.

Easy Organization Opportunities

Products that are vacuum sealed provide convenient storage choices. They food can be stored freely anywhere, whether in the freezer or pantry, because it will be tightly packed in small, portable bags.

Save the Taste

Vacuum-sealed foods are not exposed to moisture or air mixing. As a result, the taste, texture, and internal moisture are all fully kept, giving the food enduring freshness. In addition, these bags help protect the nutritional benefits.

No Additives Necessary

Vacuum sealing doesn't need any chemical additions to save food. Consumers are therefore protected from dangerous chemicals and unnecessary spending on them. The taste continues to be authentic.

Marinating in A Healthy Environment

Vacuum packaging is the best option if marinating meat. The vacuum packaging seals the moisture and original flavor.

Disadvantages

Costly

With all those features, a vacuum sealer cost quite a bit of money. A sealer can be quit expenses. This may rise depending on the machine's settings. The bags needed to package the prized object are also very expensive.

Anaerobic Bacteria

Vacuum packaging technology prevents air, mostly oxygen, from entering the package, so aerobic bacteria cannot grow, keeping the food safe for as long as it is not opened. On the other hand, anaerobic bacteria are different and can survive in an oxygen-free environment. Therefore, vacuum packaging won't ensure the food is poison-free if it’s not kept clean.

Crushes Fragile Goods

It's necessary to remove all the air from the bag before vacuum sealing. The bag's air will be completely sucked out using a suction pump. The food within is under pressure during this process, and if it is not handled correctly, it could lose its original integrity and be crushed. Therefore, discover alternative methods to vacuum sealing crushable foods instead of using the option or simply not doing so. While vacuum packaging may provide many points for health and safety, it won't be a panacea for preventing food waste. Vacuum wrapping won't sanitize the food if it is infected.

Choosing the Right Vacuum Packaging Equipment Company

To ensure you have the most constructive outcome when purchasing vacuum packaging equipment from a vacuum packaging equipment manufacturer, it is important to compare several companies using our directory of vacuum packaging equipment manufacturers. Each vacuum packaging equipment company has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each vacuum packaging equipment company website using our patented website previewer to get an understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple vacuum packaging equipment companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services