Thermoforming is a plastic manufacturing process that stretches thermoplastic material with the help of pressure or force on the mold. The mold can be of a three-dimensional shape or any other plastic shape. Thin and thick thermoplastic sheets are used to make different products. Thin sheets are used to make cups, containers, lids, trays, and clamshells. However, thick thermoplastic sheets are used to make car panels, doors, refrigerator liners, and plastic pallets. Read More…

Valk’s policy is “to meet or exceed our customer’s requirements, working together as a team with honesty and integrity.” Valk’s success is due to their long standing focus on quality & customer service.

Since 1960, Profile Plastics Inc. has been at the forefront of thermoforming technology. Utilizing the latest software and technology, our expert staff of engineers can design custom vacuum, pressure, and twin-sheet thermoformed solutions. Over the last 60 years, we have developed a process that allows us to deliver consistent, high volume, and precise products with superior quality. Our high...

Quality Plastics has been a leading manufacturer of vacuum forming since 1976. Whether you need a small batch of custom vacuum-formed parts or a large-scale production run, we have the capabilities and expertise to deliver. We are committed to providing our customers with exceptional vacuum-formed products and services that meet their needs and exceed their expectations. Contact us today to learn ...

Engineered Plastic Products custom forms & fabricates sheet thermoplastic materials, standard & specialized, for any number of industrial & commercial requirements. EPP has been widely recognized for outstanding manufacturing & service since 1958 for companies such as GE, NASA & AT&T. Custom fabricated parts can be as large as 72"x108" down to 2"x2" in any thickness up to 1 1/2". Post-forming...

At Lerner Molded Plastics, we specialize in crafting high-quality vacuum-formed products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.

RapidMade is a leader in thermoforming and vacuum forming solutions, offering unmatched customer experience, quality, and speed. We cater to diverse needs with a broad material and equipment portfolio, ensuring cost-effective, engineered parts. Trust us for reliable, timely delivery of your small to medium batch plastic projects, meeting the highest industry standards. Choose RapidMade for...

At Designcraft, we pride ourselves on being pioneers in the field of innovative design and manufacturing solutions. We specialize in vacuum forming, a versatile and cost-effective method for creating high-quality plastic components. Our team of skilled engineers and designers work tirelessly to ensure every product we produce meets the highest standards of precision and durability.

Robinson Industries offers thermoformed and injection molded reusable, heavy duty plastic pallets, packaging and more. We are one of the largest suppliers of reusable pallets to many industries.

More Thermoforming Companies

Materials Used for Thermoforming

It is known that thermoplastic is the raw material that is used for the thermoforming process. There are many thermoplastic polymers that can be heated and changed into any shape. There are two types of thermoplastic categories:

Amorphous Thermoplastic

This thermoplastic material has a random molecular structure with a wide range of softening temperatures. They have high dimensional stability, impact resistance, good bonding with adhesives, and are easy to thermoform. Some examples are polycarbonate, acrylic, and high-impact polystyrene.

Semi -Crystalline Thermoplastic

This type is best for making durable plastic parts and has excellent wear and bearing resistance, chemical resistance, and insulation properties. However, this type is difficult to thermoform as they have average impact resistance. Common examples are polypropylene, nylon, and polyethylene.

The Thermoforming Process

Thermoforming is a simple, efficient, and time-saving process. It is done by heating a thermoplastic sheet enough to make it pliable and then placing it on a 3D shape to form a mold. Each thermoforming step is to be done with great accuracy and precision to produce quality products. The steps of the process are discussed below:

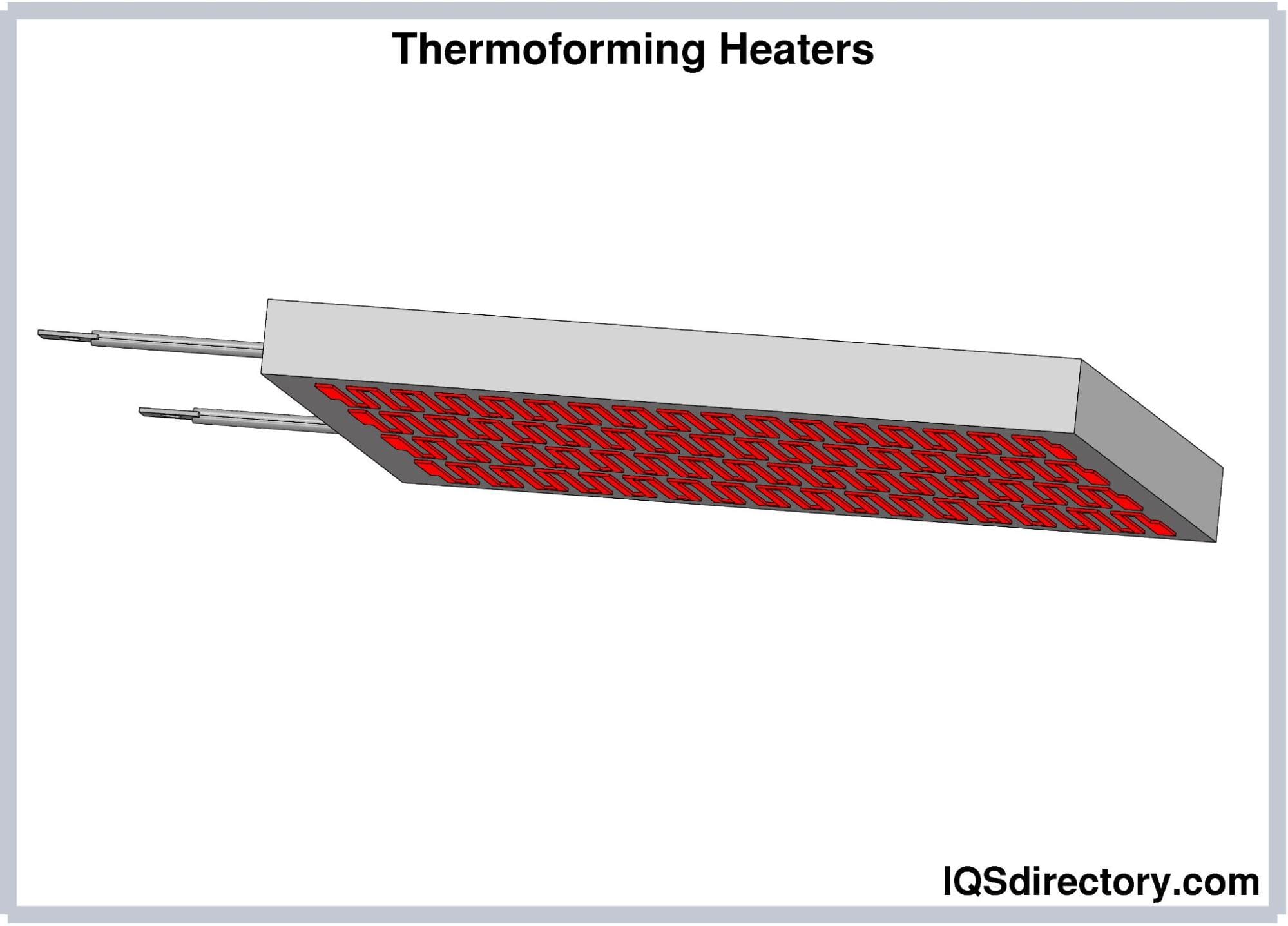

Heating the Plastic Sheets

A clamp holds a long sheet of plastic and then transports it into the heating equipment. The sheet is heated with the help of rods, exposing them to hot air or infrared heaters.

Putting Plastic Sheets Into Molds

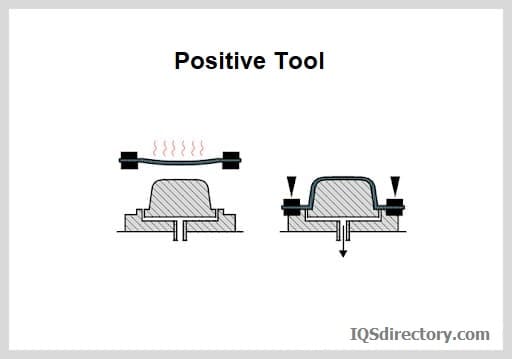

After heating the sheet, it is transported to a preheated mold tool. The heated plastic sheet takes the shape of the mold cavity, and the desired product is achieved. The tools of mold can be positive or negative depending on its form. The positive tool, also called a male mold, is convex-shaped in which the heated plastic sheet is placed above the tool.

The negative tool is also known as female mold and is concave shaped. The heated plastic sheet is put inside the mold cavity to take the desired shape.

Trimming Formed Sheets

After getting the desired mold shape, the plastic sheet is sent to the trim station, where a die or circular saw cuts the extra parts on the sheet. The trimmings are then recycled to form other parts.

Thermoforming Methods

The methods for thermoforming are vacuum forming, pressure forming, matched mold forming, and twin sheet forming. However, the most commonly used ones are vacuum forming and pressure forming.

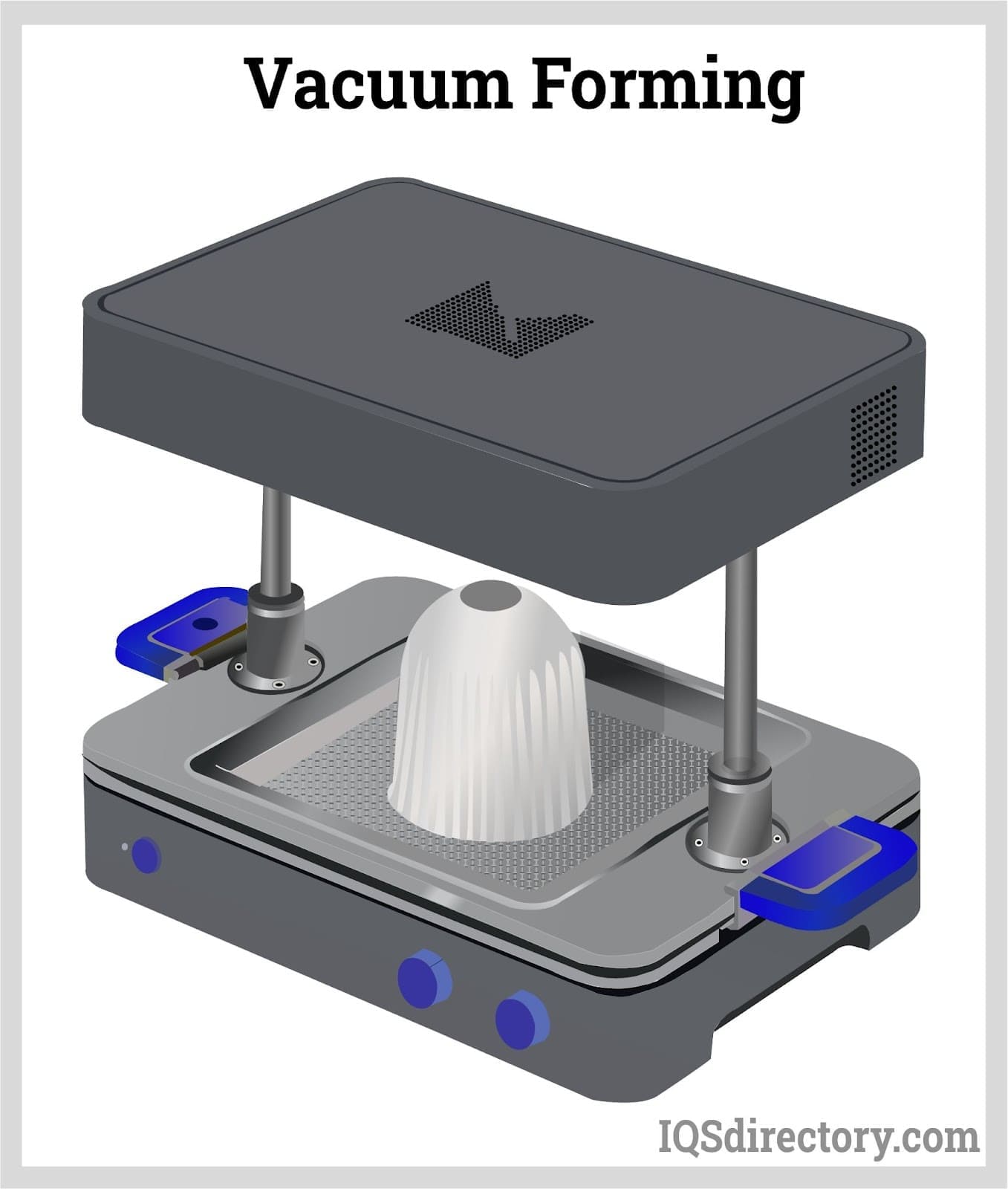

Vacuum Forming

- Vacuum forming is the simplest form of the thermoforming process.

- In this procedure, a vacuum is generated underneath the sheet, which draws the plastic sheet against the mold cavity until the desired shape is obtained.

- The vacuum pressure should be uniform to control the thickness of the part.

Pressure Forming

- This method is similar to vacuum forming.

- In this method, vacuum air pressure is also given underneath the cavity to push the plastic sheet.

- This addition of air pressure gives more details to the finished products, which are difficult to achieve in the vacuum-forming process.

- The pressure forming method is the best for making products with complex designs.

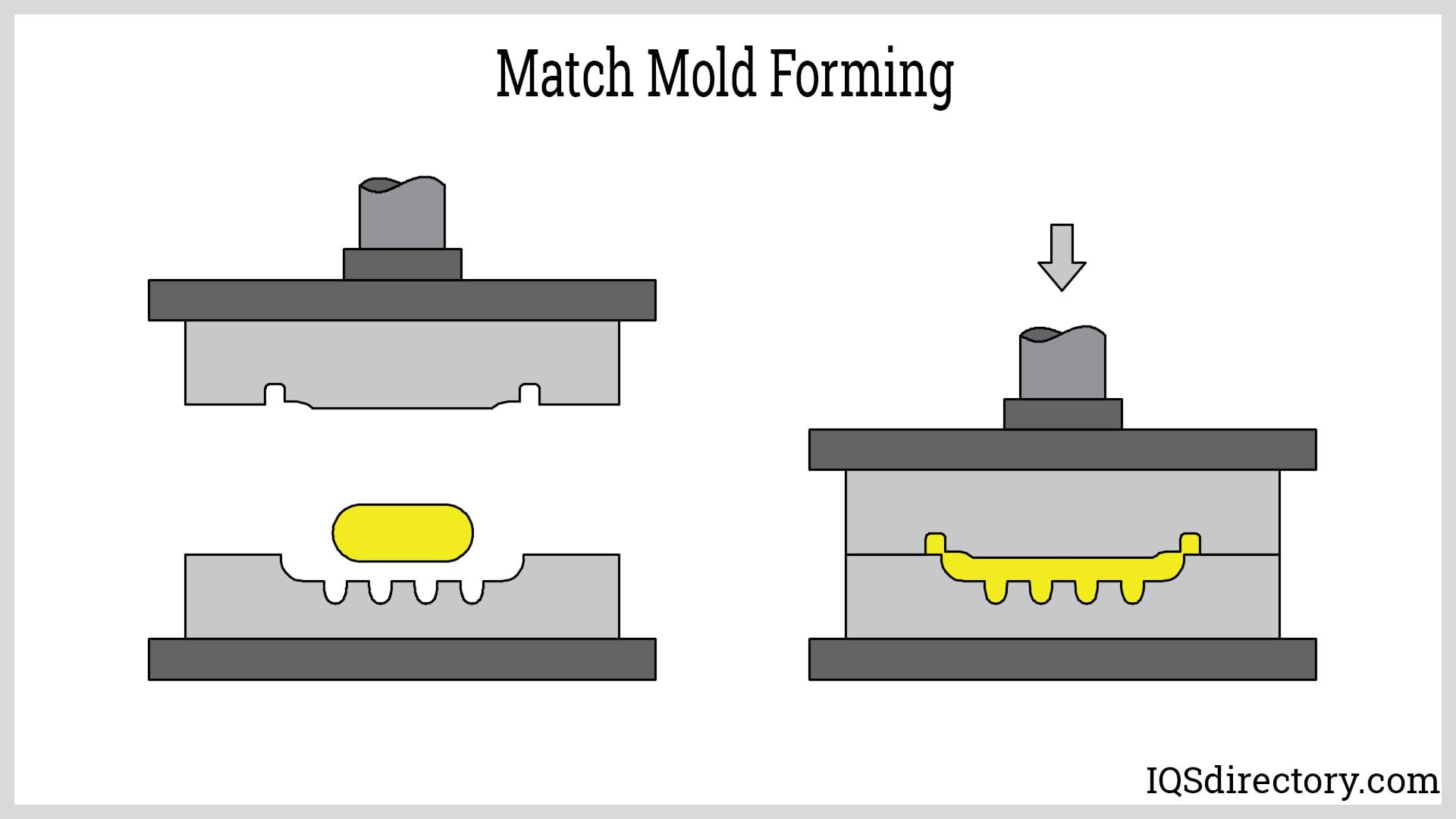

Matched Mold Forming

- Matched mold forming is a method in which heated sheets are shaped using male and female molds.

- These molds can be made of epoxy resin, wood, plaster, and metal.

- Both halves of the mold are closed, and the thermoplastic sheet takes the shape of the mold.

- Excess air is removed by using a vacuum in the mold to form a tight seal.

- This process offers the ability to create intricate and complex shapes easily.

Twin Sheet Forming

- This process is done with the help of two molds and two plastic sheets heated simultaneously.

- The two parts of plastic sheets are heated on two molds, and then these molds are pressed together to attach both parts with great care.

- Twin sheet thermoforming is used for making double-walled, three dimensional parts and hollow tubes.

- The twin sheet method is ideal for making pipes, ducts, tanks, etc.

Applications of Thermoforming

- The thermoforming method is used in various industries such as automotive, aerospace, business equipment, aviation, building and construction, medical equipment, food and beverages, recreational equipment, and dunnage and containers.

- Thermoforming is used in dashboard assemblies, interior paneling, doors, seating parts, exterior body panels, bumpers, and air ducts in the automotive industry.

- In the aerospace industry, it is used to produce aircraft interior paneling, galley components, overhead luggage bins, window shades, ducting, and light housing.

- Other thermoforming uses are in the making of trays, medical boxes, food containers, panels, machinery covers, protective casings, bins, and containers used in many other industries.

Choosing the Proper Thermoforming Company

For the most beneficial outcome when selecting a thermoforming company, it is important to compare several businesses using our directory of thermoforming companies. Each company has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each thermoforming business website using our patented website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services